Project SOLSTICE

Excerpt

New impetus to reduce or even substitute Indium and Silver in the sustainable industrial deployment of high-efficiency solar cells.

Frédéric JAY, engineer-researcher, CEA-Liten / INES

ANR reference : 22-PETA-0011

SOLSTICE aims to significantly reduce, or even eliminate, the use of critical materials such as indium and silver in industrial-scale solar cell production. The photovoltaic technologies targeted are those based on silicon, enabling high conversion efficiencies (silicon heterojunction, Topcon-like, Perovskite/Silicon tandem) while limiting production costs.

Substitute materials developed during this project have been selected for their potential optoelectrical properties, but also for their abundance and ease of access. The final cell structures will have to demonstrate high performance and increased sustainability in terms of material sourcing.

Keywords: Photovoltaic solar cell, silicon, heterojunction, topcon, PK/Si tandem, transparent conductive oxide, metal nanowires, transparent electrode, materials development, device integration, advanced characterization, artificial intelligence structure selection

Tasks

Our researches

Development of alternative materials to indium-based conductive oxides

The materials selected for this task show promising intrinsic optoelectrical properties to replace indium-based materials with one type of doping associated with the cell face (N or P). The selected N-type TCOs are Calcium or Strontium Vanadate oxides (SVO or CVO), promising in their perovskite form; the P-type TCOs will be copper iodides (CuI) and nitrogen-doped tin oxide (N: SnOx). For all these TCOs, their application and compatibility with solar cell processes will have to be assessed. Silver or copper nanowires can also be used as a transparent conductive layer (TCM). These materials are intended to act as charge carriers between the cell’s selective layers and the metal contacts.

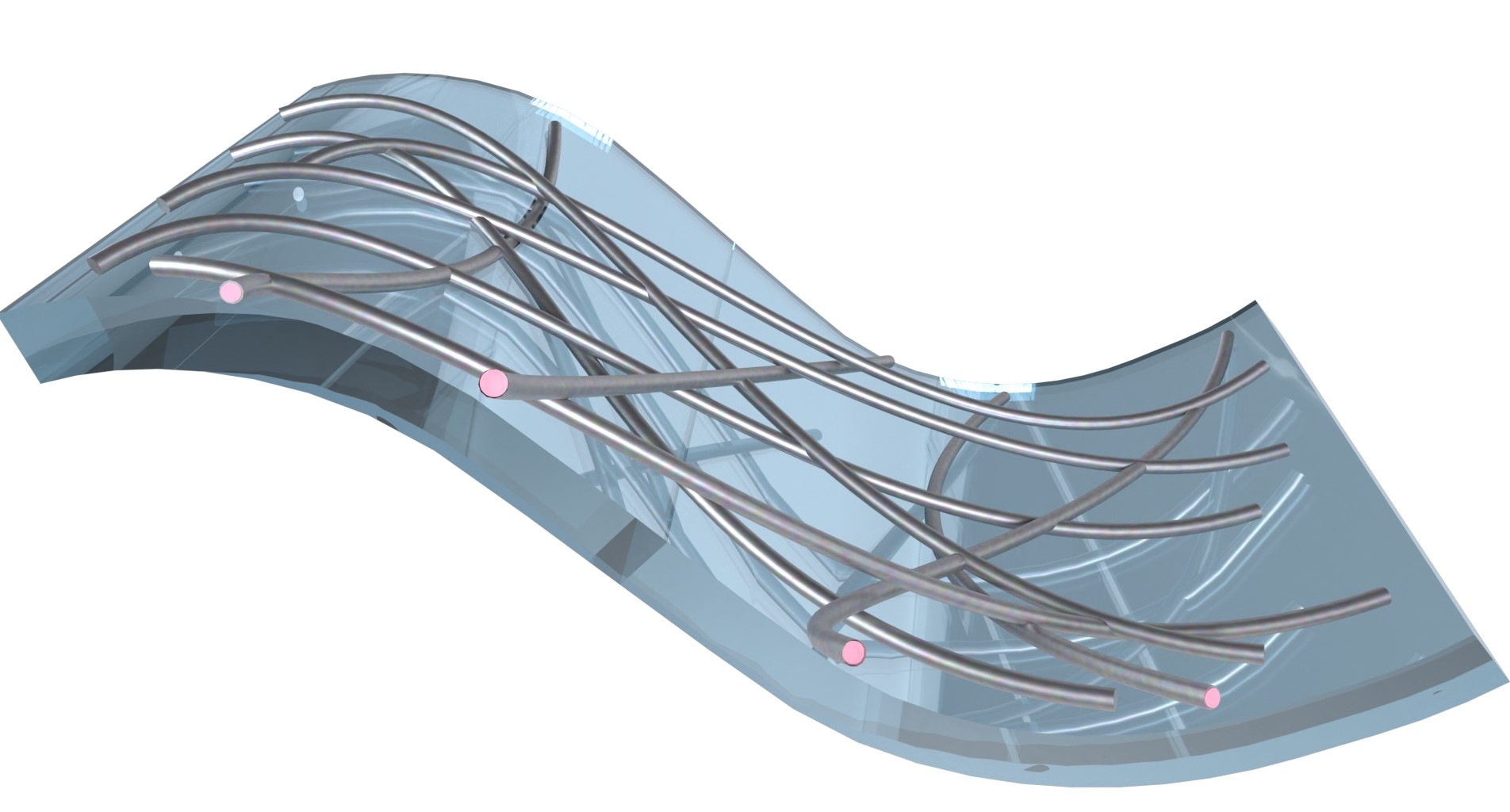

Development of silver replacement/reduction materials

Metal nanowires will be used to replace silver metallization grids as transparent electrodes. Their density will have to be optimized to replace these grids. The materials selected should have a resistivity similar to that of current metallization grids, and remain stable during operation. Core/shell materials will be evaluated for this purpose. Vanadate oxides will also be used to evaluate metallization grids with aluminum, as the electronic affinity between these two types of material is high.

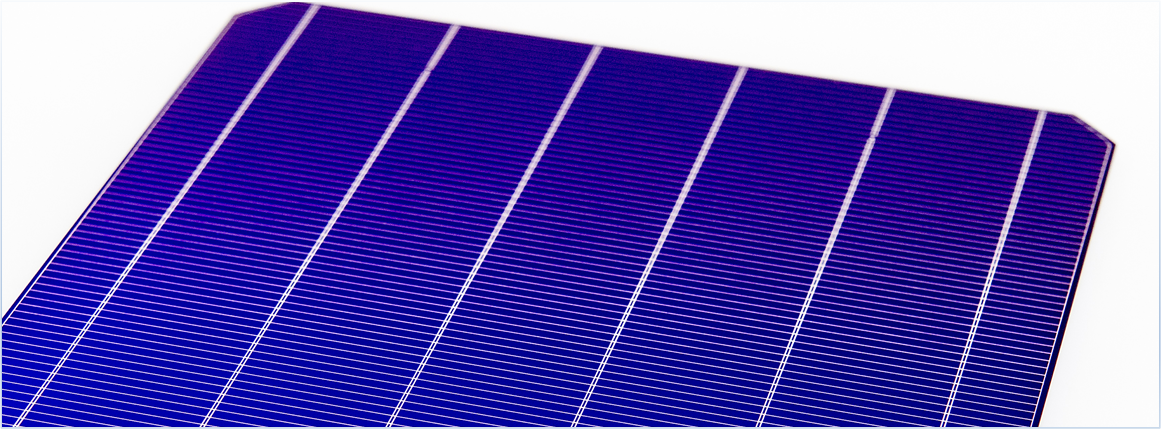

Developing solar cells using new materials

In order to evaluate the potential of these different materials, different solar cell structures will be studied, each with its own specifications. What they have in common is that they deliver high performance at relatively low manufacturing costs. For heterojunction and topcon-like structures, the processes are already industrialized and established on a large scale. They enable conversion efficiencies in excess of 25%. Tandem structures are less mature, but are positioned as the next generation of solar cells, with potential efficiencies in excess of 30%. The main differences between these structures influencing the use of the materials proposed during the project lie in their tolerance of high temperatures ranging from 150° to 500°C, or in their surface topology (textured, polished) and affinity with the underlying layers.

Choosing the best solar cell structures

The final definition of the best material/structure combinations will be made after accelerated aging tests of the devices, combined with material characterization. Artificial intelligence will be used to pool material properties, device performance and availability to provide a comprehensive techno-economic response.

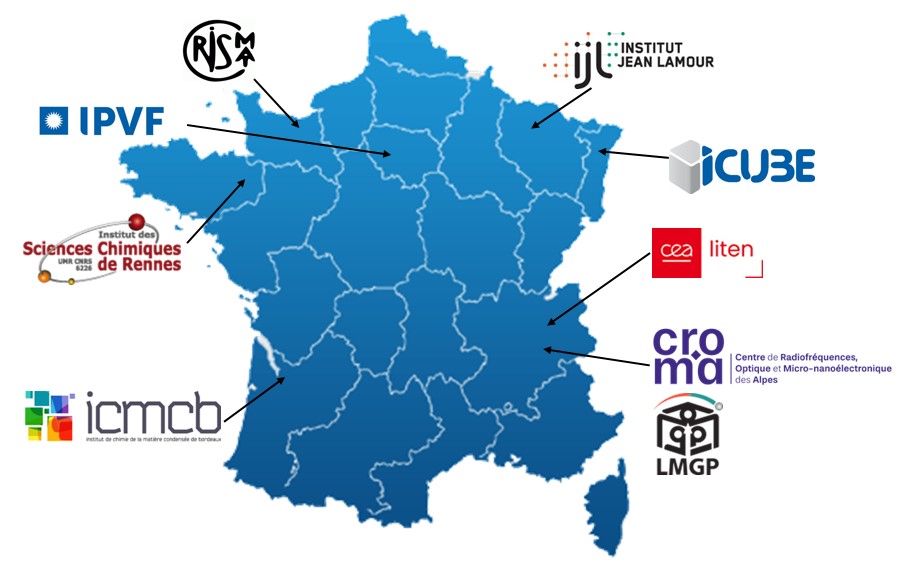

Consortium

8 academic research laboratories + 1 applied research institute

The quantities of Indium and Silver used in the production of silicon-based solar cells pose a problem for the deployment of production capacities in excess of the projected Terawatt needed to decarbonize energy production. The aim of the SOLSTICE project is to propose alternative materials to overcome future supply problems for critical materials, while continuing to bring these technologies to maturity (in terms of efficiency and reliability).

Solar cell technologies are a first lever for decarbonizing energies. However, the use of materials available in limited quantities would tend to increase the cost of these materials in the medium/long term, and would also exert significant pressure on land through increased mining. The use of abundant or little-used materials would avoid these two problems. The final structures proposed will take into account the mining and toxicity of the materials through technical and economic analysis.

Pooling the knowledge of 9 laboratories/institutes with complementary skills ranging from materials and devices to advanced characterization and artificial intelligence. The project will include the training of 5 post-docs and/or research engineers, 2 PhD students and 9 end-of-study interns in addition to the researchers involved in the project.

No news

Publications

More projects